Our vacuum capping machine is engineered with a mechatronic design and incorporates a PLC-based fiber optic sensing system, allowing for adjustable vacuum pressure to suit specific requirements. Its superior performance guarantees product quality throughout the shelf life, making this capping machine a perfect fit for the food and pharmaceutical sectors. Additionally, it is designed to integrate seamlessly with filling lines for products like jams and canned goods, enhancing efficiency and reliability in production processes.

Glass jars or bottles with tinplate cap.

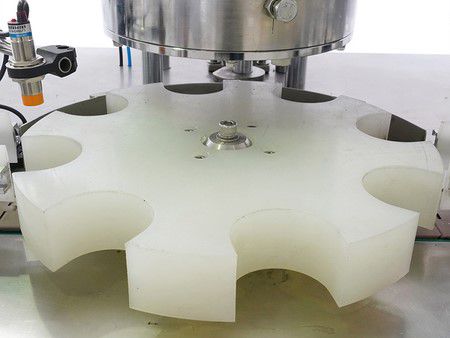

Container feeding-Vacuum application-Capping-Discharge

The vacuum capping machine features an advanced electronic sensor and a Programmable Logic Controller (PLC) integrated with a touch screen control system. The capping machine is equipped with a graduator positioning system that ensures precise placement of caps, and an pneumatic gripping system that optimizes the vacuum sealing process.

Constructed from high-quality stainless steel, the vacuum capping machine promises long-lasting performance and resistance to wear and tear, making it suitable for the demanding environments of the food and pharmaceutical industries. It also includes an oil-cooling vacuum pump that efficiently maintains the machine's performance even under continuous operation. The inclusion of a negative pressure tank enhances the machine's ability to achieve an optimal vacuum level for each container, ensuring the integrity of the seal and the preservation of the product.

Specifications| Cap size | 38-82mm |

| Applicable bottle diameter | 30-120mm |

| Capping speed | 25-35bpm |

| Air pressure (vacuum) | 0.4-0.8Mpa/0.01-0.06Mpa |

| Power supply | 220V, 50Hz, 3.0kW |

Capping machines are pivotal in various industries for attaching or securing caps, lids, or closures to bottles or containers. They are versatile and can be tailored for numerous applications, including general packaging, industrial use, food and beverage processing, agriculture, chemical, and cosmetic industries.

A capping machine is designed to handle specific types of caps and bottles. Once configured for a particular packaging line, it can efficiently manage caps and bottles within the predetermined size range, provided they adhere to the type of capping it is designed for.

Depending on the efficiency requirements of the filling line, the available capping machines include automatic, manual, and semi-automatic models, each designed to meet different operational needs.

When choosing a capping machine, important considerations include the production line's filling speed, ease of use, compatibility with the bottle and cap sizes, and the machine's maintainability and durability to ensure long-term operational efficiency.

From individual filling machines to complete packaging lines, we've got covered!